Navigating the Path to Electrification: Balancing Sustainability with the Practical Demands of Refuse Collection

FEATURED In Waste Advantage Magazine

December, 2024 Issue

The push to reduce emissions in the refuse industry continues to grow. Electrification of collection vehicles plays a central role in achieving these goals. Using a data-based approach and leveraging OEMs with electrification experience can help haulers navigate to the right decision for their operation.

By Tony Giles

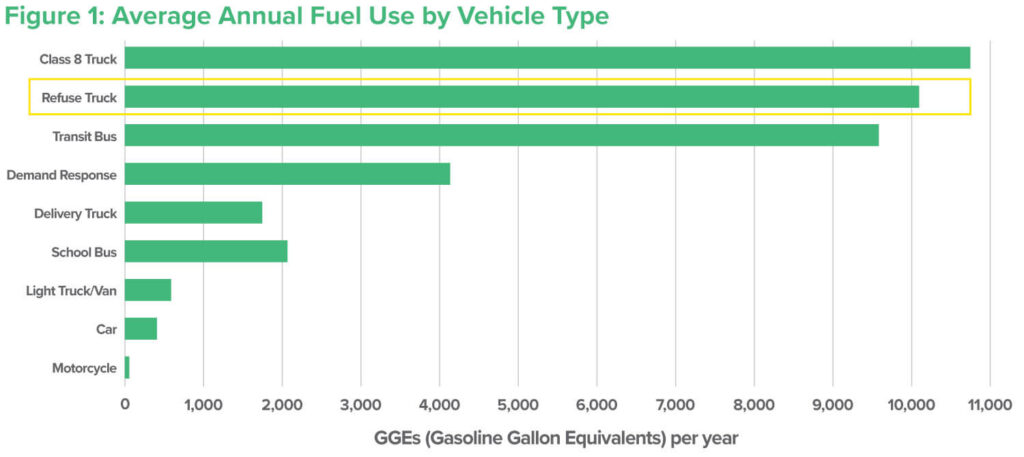

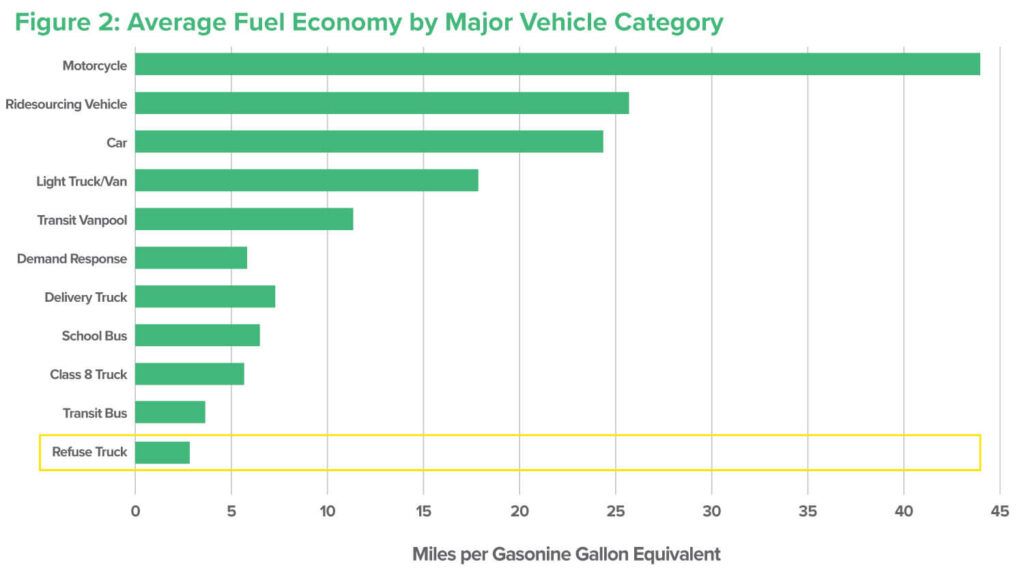

Refuse collection is a critical industry that people depend on every day. However, refuse collection vehicles (RCVs) are one of the most emission-intensive vehicle types—due to the number of miles driven daily combined with low fuel economy (see Figures 1 and 2). How can the refuse industry reduce its carbon footprint, yet still get the trash picked up every day? This article will discuss the key variables that can help fleet managers determine the optimal sustainability solution for their specific hauling operation.

Reducing Fuel Consumption

The principal goal of electrifying the refuse collection industry is to improve people’s lives—through the reduction of GHG emissions. There are secondary benefits of course, including reduced noise pollution. But the fundamental objective is to reduce fossil fuel consumption. As referenced in Figure 1, the average annual fuel use of a reuse collection vehicle is approximately 10,000 gallons. According to the EPA, 10,000 gallons of diesel is equivalent to 101.8 metric tons of CO2 emissions. Refuse vehicles are therefore a prime candidate for emission reduction efforts.

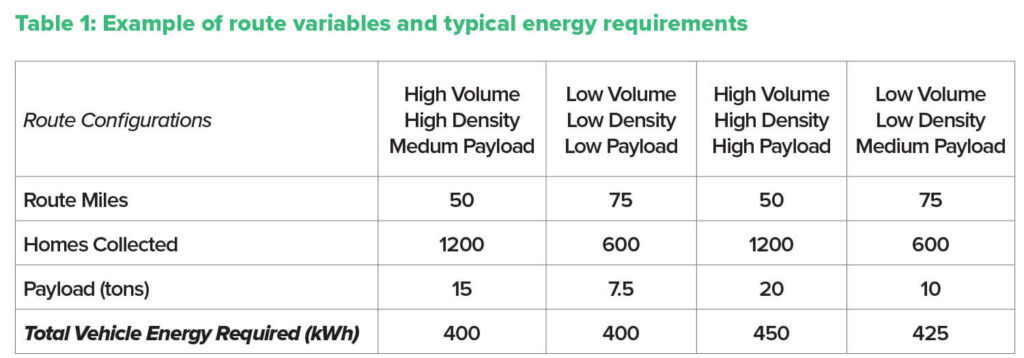

Fuel consumption of a collection vehicle is a function of route variables such as total miles, payload, topography, and number of collections. Not all routes are created equal, so it is key to understand routes and optimize the vehicle for each application. When considering electrification of your fleet, use data to make the right decisions. A combination of vehicle telemetry and back-office software can provide most of the key parameters of your routes. The next step is to translate these variables into energy requirements to determine if an electric RCV will meet the requirements.

Table 1, provides an example of how route variables and energy requirements can be summarized.

The examples in Table 1 illustrate how route variables can impact the vehicle energy requirements. Mileage, payload, and number of homes serviced all have an influence on energy requirements. Payload requirements are especially important to evaluate due to the outsized effect of compaction energy plus the adverse weight impact of EV batteries.

There are three basic outcomes from the route analysis:

- Scenario 1: Routes that are fairly low risk to electrify with existing class 8 vehicle capabilities

- Scenario 2: Routes that are not practical to electrify with EV capabilities available today

- Scenario 3: Routes that fall in the uncertain range between.

- Scenario 1 obviously delivers the maximum emissions reduction for a vehicle. Using the data from EPA discussed earlier, replacing your diesel RCV with an electric RCV eliminates approximately 100 metric tons of CO2 emissions per vehicle per year. It would be ideal if all routes fell in this category, but that is unfortunately not today’s reality.

So, what about scenarios 2 and 3, which most likely represent the majority of today’s operational routes? And we cannot ignore the vehicle charging requirements—cost and availability of charging infrastructure can also influence sustainability plans. If 480VDC power is not readily available, there could be a major capital project required before you can hit the road with an eRCV.

Thankfully, there are alternatives for those hauling fleets that face these challenges yet still want to make progress on their sustainability goals. For these routes, consider an electric side loader body (eASL) as a straightforward option to achieve a significant level of GHG reduction. An eASL that is powered with its own independent battery completely eliminates power take-off from the chassis: reducing energy requirements—and therefore fuel consumption. This reduction in fuel consumption can reduce your carbon footprint—and increase your bottom line.

Sustainability Goals

Evaluating Scenario 2

For an application where today’s class 8 electric chassis do not have sufficient energy and range, an eASL can provide an immediate solution to advance your sustainability goals. With an independent battery to power the body functions, an eASL can ‘plug and play’ into your existing diesel or CNG operation without disruption. The electric lift arm and compaction system have no hydraulics, which eliminates pumps, valves, and hoses that are prone to failure and messy environmental incidents. The electric functions of the eASL are also much more efficient than hydraulics. This efficiency enables the body battery size and weight to be reduced to a level where there is no impact to payload capability. And the benefit of fuel savings will reduce your carbon footprint in a meaningful way. These fuel savings can add up to 3,000 gallons per year, which equates to a reduction of 36.2 metric tons of GHG emissions per year per vehicle.

What about charging? eASLs use level 2 charging (240VAC), which is much more readily available and lower cost than 480VDC. Equipped with a low-cost charger (that you can buy from Amazon or Tesla) means your electric side loader is powered for business.

Looking at Scenario 3

Routes that fall into scenario 3 can be especially frustrating for fleet operations that want to go full electric. The route variables and energy calculations may be close—but not quite sufficient—to support a transition to electrification without risking productivity. Most operations cannot afford to add more collection vehicles for the same routes, so it is important that eRCVs are on par with existing vehicles that use traditional fuel sources.

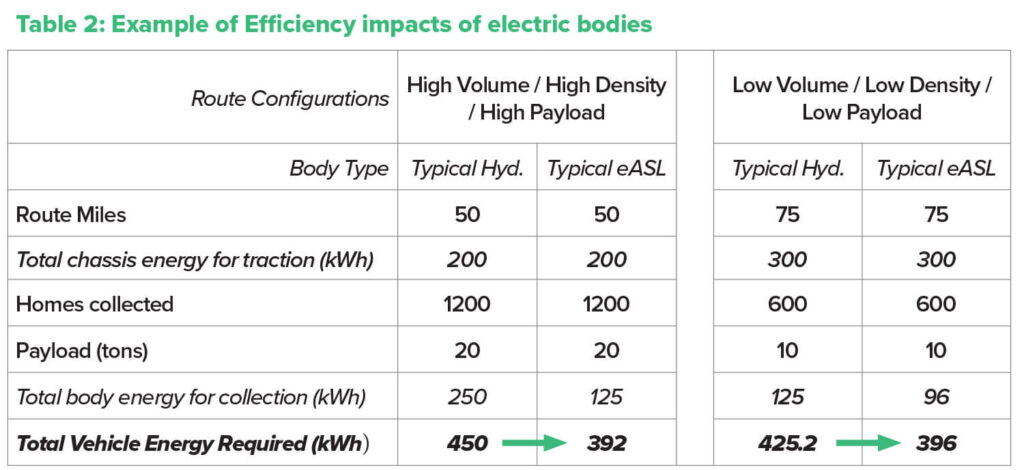

Fortunately, the benefits of the independent power supply of an eASL can also apply in scenario 3. Eliminating the power take-off enables the chassis battery to be 100 percent dedicated to traction power (moving the vehicle). Simply put, this extends the range of your vehicle and can shift the route from scenario 3 to scenario 1.

Table 2 is an illustration of the efficiency impact of an eASL on two of the previous route examples. Routes that were once considered too risky for electrification due to their energy consumption can now be comfortably within the range of an eASL.

Putting It All Together

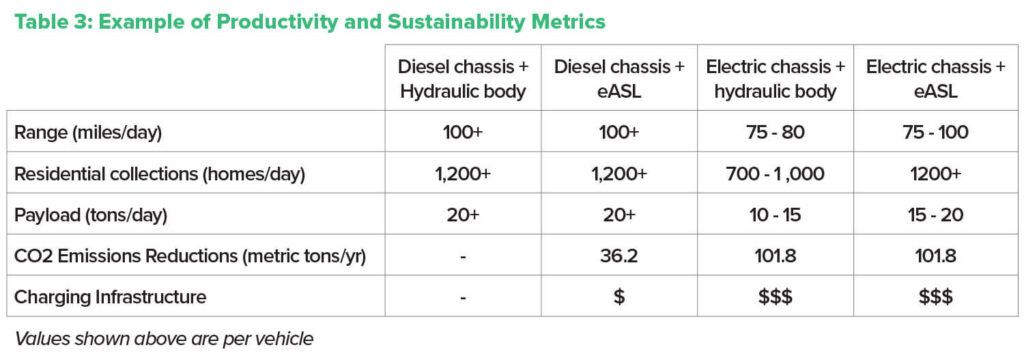

Table 3 is a general summary of some of the important productivity variables, and illustrates how the different vehicle configurations can impact both sustainability and productivity goals.

The values in Table 3 are indicative only; there is still variability in applications that cannot be distilled into one single number. Therefore, it is important to understand these variables for your specific operation, and partner with equipment suppliers that use a data-driven approach to demonstrate results.

A Central Role

The push to reduce emissions in the refuse industry continues to grow. Electrification of collection vehicles plays a central role in achieving these goals. There are real challenges to electrification of refuse collection vehicles, and there is no one-size-fits-all solution that will work for every application. As battery technology continues to evolve, electric vehicles will continue to expand their capabilities and become more prevalent in the waste collection industry. However, there are alternative solutions commercially available today that are proven to reduce fossil fuel consumption and the associated emissions. Using a data-based approach and leveraging OEMs with electrification experience can help haulers navigate to the right decision for their operation.

Tony Giles is the Alternative Fuels Product Manager at Environmental Solutions Group and has focused on electrification of the refuse industry for the last three years. Environmental Solutions Group is a division of Terex that serves the solid waste industry through its integrated family of brands including Heil refuse trucks, 3rd Eye digital products, and Soft-Pak software solutions. Tony can be reached at [email protected].